CONDITIONING BEFORE REUSE, THE ESSENTIAL STEP

In the LIFE CLOOVER² reuse circuit, each container must meet hygiene, functionality, and safety conditions before being reincorporated for a new use. For this reason, the washing and reconditioning carried out by the company VICENTE BALLESTER RÍOS, S.L. becomes an essential step to guarantee the quality of the process. After use, the industrial drums are returned to the facilities of AGROFRESH FRUIT PROTECTION S.A. Afterwards, they are taken to VICENTE BALLESTER RÍOS, S.L., an external company specialized in washing and conditioning industrial containers, where they go through a process that includes:

- Reception and inspection of the general condition of the container.

- Industrial washing, with separation of residues and product remains.

- Drying and verification, checking the integrity of the drum.

THE PLASTIC CRATES LOOP ADVANCES WITH NEW DEVELOPMENTS

7 de octubre de 2025

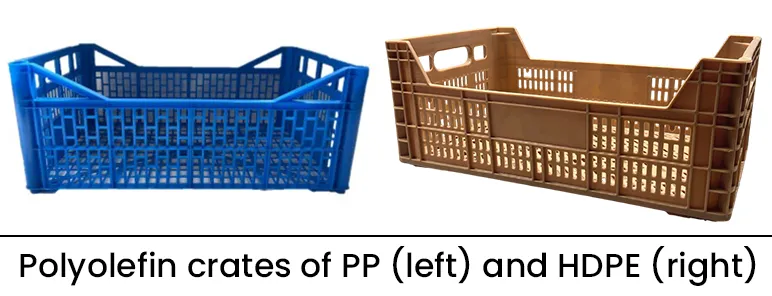

7 de octubre de 2025The closed-loop system for horticultural plastic crates has introduced new developments in the HDPE crate format. LIFE CLOOVER² includes two types of plastic crates: lightweight ones made of PP and heavy-duty ones made of HDPE. The lightweight PP crates (weighing 0.458 kg each) have already been manufactured, sent to the packer, and distributed to customers. A first usage cycle has been completed with the participation of Agropons S.L., one of the members of AMAFRUVA (Asociacion De Mayoristas Asentadores De Frutas Y Verduras De Valencia). The results are currently being analysed and will be reported soon. The heavy-duty HDPE crates (weighing 1.0 kg each) after a change in supplier, have already been manufactured and have now been delivered to the packer to start their initial cycle. Both types have been manufactured using virgin material and feature distinctive colours compared to the crates typically used in this sector (horticultural): blue for the lightweight PP crates and light brown for the heavy-duty HDPE crates. Additionally, discussions are underway with companies in Andalusia to replicate the model in other autonomous communities besides the Valencian Community.

COLOURED PLASTIC CABLE TIES: THE LANGUAGE OF THE LOOP

11 de septiembre de 2025

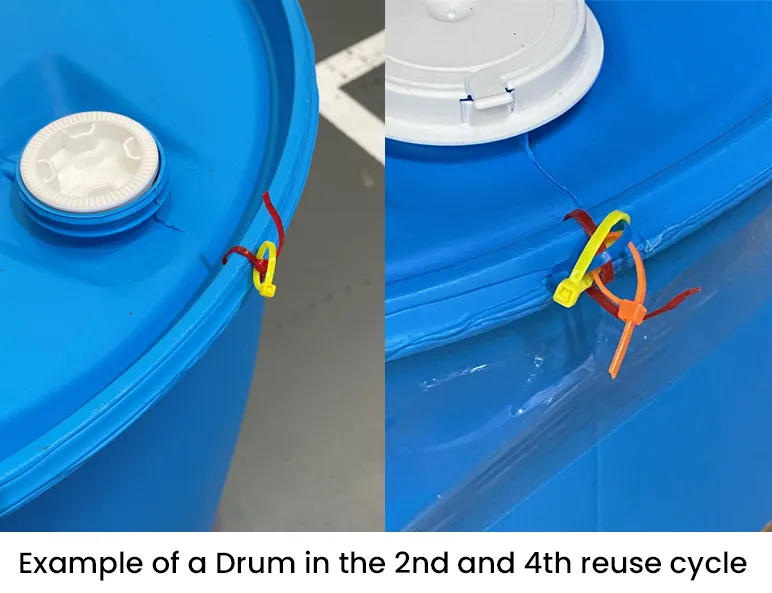

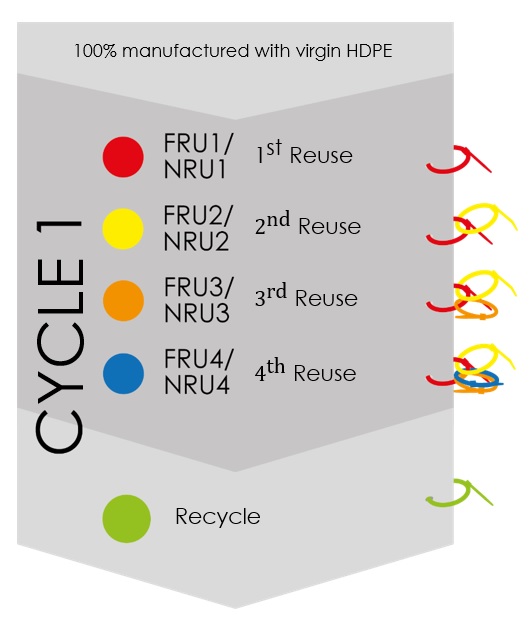

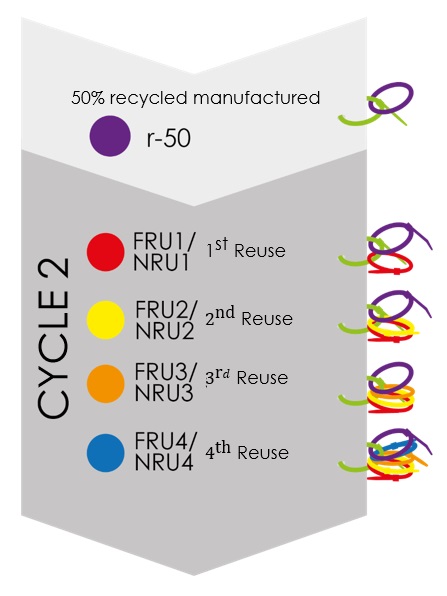

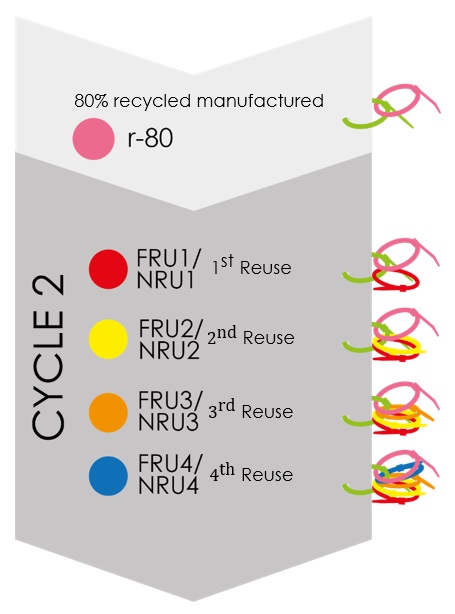

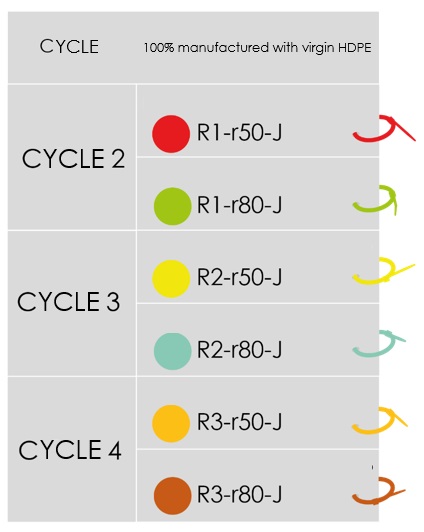

In LIFE CLOOVER², traceability of reusable containers is a key pillar to ensure efficient and safe management. To achieve this, we have implemented a colour-coded plastic cable tie system, which allows quick identification of each container’s position within the reuse cycle. Each colour represents a stage in the process — from the first use, through every reuse cycle, to its preparation for recycling. This visual coding system simplifies logistical control, improves operational efficiency, and enables informed decision-making. How does the system work? Each container is marked with its own colour code, applied using cable ties as visual markers:

In LIFE CLOOVER², traceability of reusable containers is a key pillar to ensure efficient and safe management. To achieve this, we have implemented a colour-coded plastic cable tie system, which allows quick identification of each container’s position within the reuse cycle. Each colour represents a stage in the process — from the first use, through every reuse cycle, to its preparation for recycling. This visual coding system simplifies logistical control, improves operational efficiency, and enables informed decision-making. How does the system work? Each container is marked with its own colour code, applied using cable ties as visual markers:

- In the case of drums, which go through multiple reuse cycles, a new coloured plastic cable tie is added with each use.

This sequence makes it easy to identify how many times a container has been reused. Additionally, new specific plastic cable ties will be assigned when these drums are manufactured using 50% or 80% recycled material.

colour-coded cable tie for food (FRU) and non-food (NRU) drums.

colour-coded cable tie for food (FRU) and non-food (NRU) drums. - On the other hand, Jerrycans, are not reused but are recycled and remanufactured. In each new production using recycled material, an identifying cable tie is added to indicate the percentage of recycled content used (50% or 80%), clearly distinguishing their composition.

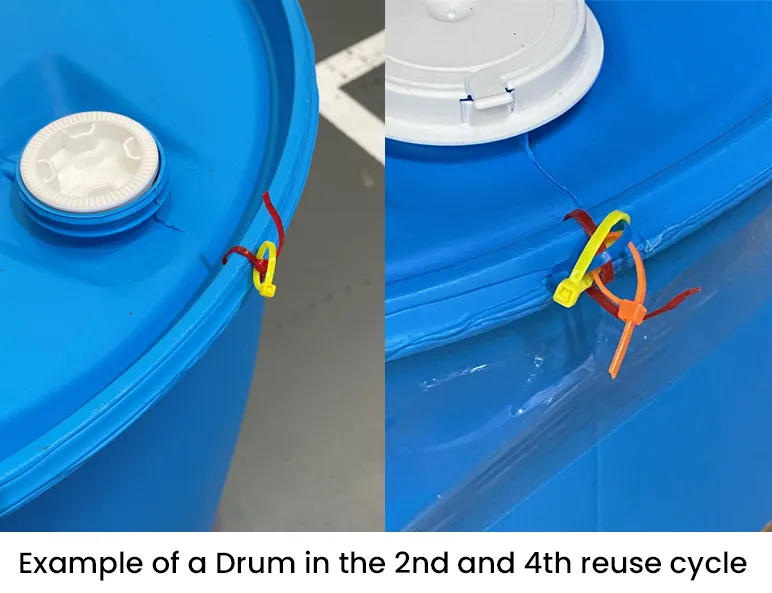

WE HAVE REACHED THE 4TH REUSE CYCLE OF INDUSTRIAL DRUMS!

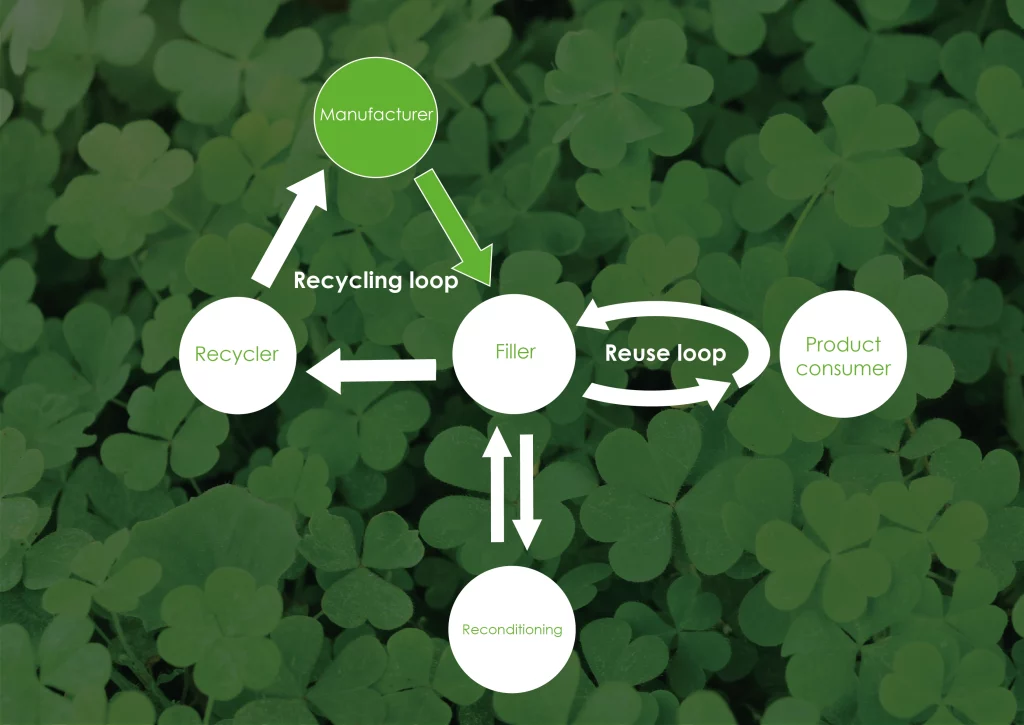

We are pleased to announce that the industrial drums used in the LIFE CLOOVER² project have reached their 4th reuse cycle, achieving one of the key milestones of our circular economy model, which combines reuse with recycling. These drums, made from virgin high-density polyethylene (HDPE) by our partner company Reyde S.A., were eco-designed from the outset with durability and multi-use capability in mind. Since their initial distribution, the drums have followed a closed-loop process that includes:

- Filling with citrus waxes (for food drums) and detergents (for non-food drums) at AgroFresh Fuit Protection, S.A. facilities

- First use, followed by recovery and return.

- Washing and reconditioning, ensuring safety and full functionality in each new cycle.

- Identification and traceability, using coloured plastic cable ties that allow us to track the cumulative use of each container.

Each industrial drum has been identified with coloured plastic cable ties, an essential part of our visual traceability system. This system allows the immediate recognition of the number of accumulated uses for each container, ensuring proper management within the closed-loop circuit. Thanks to this colour-coded system, we can accurately track the individual journey of each drum, reinforcing transparency and logistical control.

Each industrial drum has been identified with coloured plastic cable ties, an essential part of our visual traceability system. This system allows the immediate recognition of the number of accumulated uses for each container, ensuring proper management within the closed-loop circuit. Thanks to this colour-coded system, we can accurately track the individual journey of each drum, reinforcing transparency and logistical control.

LIFE CLOOVER² PTC MEETING UPDATE

10 de octubre de 2025

On September 5, 2025, the partners of the LIFE CLOOVER² project convened for the latest Project Technical Committee (PTC) meeting. This session provided a valuable opportunity to review project progress, share key milestones, and align on the upcoming steps to further advance the circular economy initiatives integral to LIFE CLOOVER². Key topics addressed during the meeting included:

On September 5, 2025, the partners of the LIFE CLOOVER² project convened for the latest Project Technical Committee (PTC) meeting. This session provided a valuable opportunity to review project progress, share key milestones, and align on the upcoming steps to further advance the circular economy initiatives integral to LIFE CLOOVER². Key topics addressed during the meeting included:

- Comprehensive project updates highlighting recent achievements.

- Progress in the industrial and commercial reuse loops, focusing on container lifecycle management.

- Development status of the digital platform designed to enhance traceability and data management.

- Updates on external certifications related to recycled content and circularity compliance.

- Planning of future meetings to ensure ongoing coordination and effective collaboration among partners.

The Technical Phase of the LIFECloover² Project Begins to Revolutionize Plastic Packaging Management in the Agri-food Sector

19 de mayo de 2025

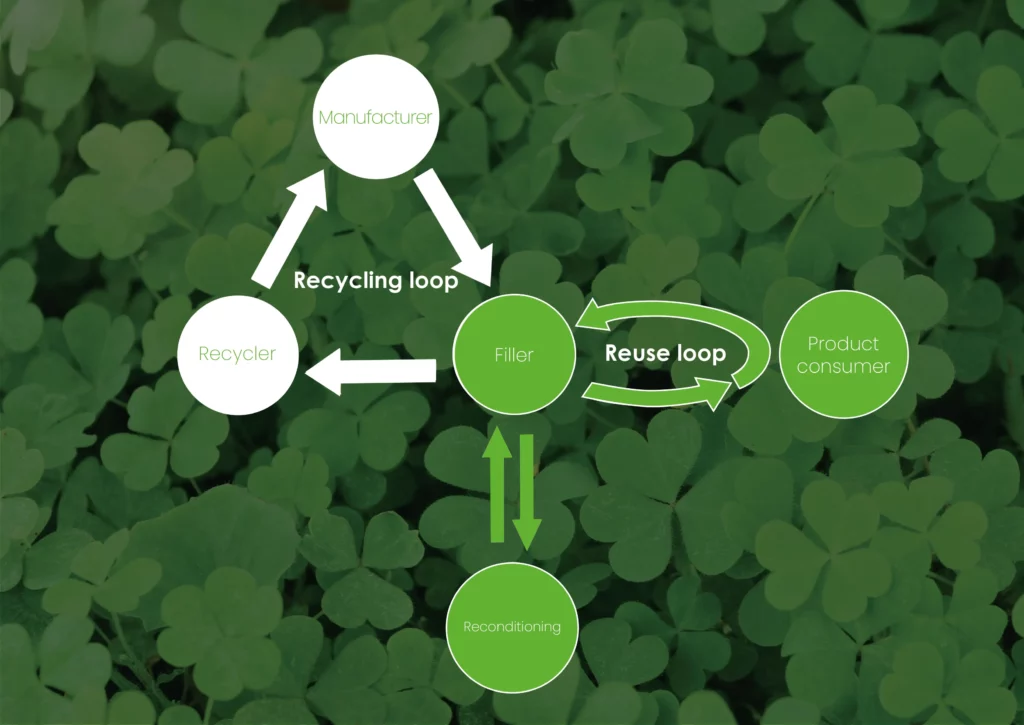

After a year marked by numerous events and climate-related challenges, the LIFECloover² Project has officially entered its technical phase. This new stage involves the manufacturing of reusable and recyclable polyolefin drums, jerrycans, and crates, aiming to transform the use of packaging in the agri-food sector through a sustainable, traceable, and certified approach. The goal of LIFECloover² is to first implement a holistic, scalable, and certified circular economy system in Spain, and then replicate it in other European Union countries. This system will enable the reuse and recycling of rigid plastic containers—such as drums and crates—while ensuring compliance with the stringent food safety standards established by the European Food Safety Authority (EFSA). The launch of the technical phase comes after a particularly difficult period. On October 29, the project faced a major setback due to the DANA (Isolated Depression at High Levels) that severely impacted the Valencia region. Three of the project’s seven partners, all based in this area, were heavily affected by the extreme weather event, which left a devastating toll: 219 fatalities, 87 municipalities affected, over 48,000 businesses damaged, and economic losses exceeding €13.3 billion. Despite these challenges, the project partners responded swiftly by activating the Risk Management Plan, reaffirming their strong commitment to the goals of LIFECloover². Their determination reflects a broader vision for a more sustainable, circular, and secure Europe in the field of plastic packaging for the agri-food industry. The project has undergone several changes, and new developments will soon be revealed—changes that will undoubtedly strengthen both the progress and the outcomes of LIFECloover²

After a year marked by numerous events and climate-related challenges, the LIFECloover² Project has officially entered its technical phase. This new stage involves the manufacturing of reusable and recyclable polyolefin drums, jerrycans, and crates, aiming to transform the use of packaging in the agri-food sector through a sustainable, traceable, and certified approach. The goal of LIFECloover² is to first implement a holistic, scalable, and certified circular economy system in Spain, and then replicate it in other European Union countries. This system will enable the reuse and recycling of rigid plastic containers—such as drums and crates—while ensuring compliance with the stringent food safety standards established by the European Food Safety Authority (EFSA). The launch of the technical phase comes after a particularly difficult period. On October 29, the project faced a major setback due to the DANA (Isolated Depression at High Levels) that severely impacted the Valencia region. Three of the project’s seven partners, all based in this area, were heavily affected by the extreme weather event, which left a devastating toll: 219 fatalities, 87 municipalities affected, over 48,000 businesses damaged, and economic losses exceeding €13.3 billion. Despite these challenges, the project partners responded swiftly by activating the Risk Management Plan, reaffirming their strong commitment to the goals of LIFECloover². Their determination reflects a broader vision for a more sustainable, circular, and secure Europe in the field of plastic packaging for the agri-food industry. The project has undergone several changes, and new developments will soon be revealed—changes that will undoubtedly strengthen both the progress and the outcomes of LIFECloover²